your'e looking for a cantilever detail, basically. that's not going to be a standard framing condition. will take some engineering thinking beyond normal framing rules. you don't have an engineer?

the header(s) might have to be pretty hefty, though, depending how much wall/ceiling/roof above it you're supporting. you don't want the corner to sag. and the ends of the headers over each 1/2 of the window will have to be tied together in a rigid way.

do you still want a support column in the corner or two structural beam headers canted and the windows are a storefront system or a special field mull?

the column in the corner is typical for standard windows with a nail fin & the column can be either wood or steel...

with stick construction, it's really not a good place for a window because all of the weight from above the corner will have to be absorbed by the header and transfered to the support on either side of the window. that could be a substantial amount of weight. you'd have to design the header almost like a beam. corner windows (unless very small) are more suitable for frame construction.

Steven, no window around the corner and no FLW either.

I have a 36" staircase with an exterior wall on the one and an interior wall on the other side. To get in some light (and make my facade work) I wanted to make the window as wide as possible. I was hoping there was a simple way of spanning the window across the full 36".

This is affordable housing, so it would have to be a simple solution. (Third and top floor.)

I dare not say what window...

it's Milgard, white vinyl.

Typically I have been staying about 3" clear of corners with all windows and doors to accommodate for double studs. I was hoping you could push these into the corners so that the window (incl. frame) is 36" wide.

metamechanic - is your CAPS still on from noting plans?

You mean like these? This is a very risky detail and not suitable for wet climates. Really, it's not that hard, but an engineer will have to size not only the cantilevering headers (allow 2/3 backspan), but also the hanger/Simpson tie where they meet at the corner depending on the size of the opening:

You may be able to get away with (2) 2x8s for the header (small corner window) but might have to have a PSL, LSL, or even a glulam for larger cantilevered openings.

Another thing to be careful of is the window - most manufacturers won't make this window or will make it but won't warranty it. You & your client have to measure the risk and put some faith in the glazer, window installer/manuf. and the sealant at the glass on glass corner. Good luck.

Just for my understanding: how would you place the studs at the T-intersection of the two walls? In our standard detail the stud prevents you from placing the window right into the corner.

to span the 36" you dont need a jamb stud, you already have a meaty corner post assembly. your sill will butt into that and you'll jack stud to the plate. Just shim tight. Im still confused about the corner - you want the glass to for a right angle or (2) window units to form a right angle? Does milgard even make a corner window?

As for the header - it depends a lot on the roof but really a plywood sheathed diaphram whith tension straps or if it goes to clg hgt just canteliever some joist out and be done.

it seems like this may not be the best solution for an affordable project especially with vinyl windows. you are still going have to trim the vertical out, and will not have any control about how each window is placed in the field. it's gonna be tough to get any kind of clean interior finish to look seamless, and the exterior resolution of how the siding and/or trim will be awkard at best.

The question is: where does the nail-fin of the window assembly attach to. How about the window flashing? You got an inside corner there.

I understand your pain; this condition is no big deal in masonry type construction but in wood frame construction? To come up with a detail that does not leave some 2" wide stucco or drywall on the side of the window is a real challenge. What dml is showing is very nice but custom and when you look at the left side of the window, 1st photo, you will notice that left-over strip of drywall that spoils the fun. I bet you in plan this glass was going right against the wall.

tsquared vixen

Can you share the detail of that vertical window over the patio door? Wood frame construction? How did you flash that window frame? You got all the conditions mleitner is looking for right there.

I noticed that about dml's image too. The two glass panes meeting distract from it a bit. I guess posting the window corner showing two windows was misleading. It is just one window in my situation.

The horizontal window in tsquared's photo seems to be exactly the condition I am trying to achieve - just using vinyl windows in wood framing. As emaze said, the tolerances will probably ruin the look.

Thanks for the input though - I will definitely save this thread for future reference.

It really isn't that complicated. It needs two cantelievering headers meeting at the corner. It can be doe in wood but probably easier to done in steel

i've never done it so i'm just throwing ideas around. can you use a vinyl retrofit window that are finless and can be screwed through the frame and into the jamb, sill, and head?

in the wall that extends past the window, i'll call it wall A, the one at the bottom in your drawing, can you:

-nail a 1x on 2-2x4 blocking/jamb. (the 1x becomes a spacer so that the 7/8" plaster ends and overlaps the window frame by about 1/8") i'm also assuming that the exterior is plaster

-wrap flashing over the 1x and out, covering the 1x and portion of wall A. flash the head, sill and the other jamb per standard practice.

-install the window by nailing through the frame. the window installer should know where to put all neccessary sealants.

-install lath and plaster ground against the window frame. the plaster ground will be the barrier between the plaster and the window frame. you will have to add a nailer in Wall A for the plaster ground to nail onto.

inside, i'm assuming it will be 5/8" drywall, the drywall will end at the 1x. and since the 1x is thicker than the drywall, there will be a reveal. i don't know the best solution. i just wanted to point out the difference in dimensions and the 1x will be exposed inside, unlike the overlap that is happening with the plaster and the frame.

i like that. it wouldn't necessarily have to be plaster on the exterior. it could be siding. instead of a 1x, you could just use a shim of whatever depth necessary to make the gyp flush with the outside of the window frame.

also, you might be able to use a window with the fins if you think the 1x is wide enough as a mounting surface for the fin and that the 1x will not split after you drive a screw in. might have to drive the screw angled towards the 2X. milgard's installation instructions for their flanged windows says that if necessary, the fins may be cut off, which makes me wonder whether those flanged windows can be mounted with screws through the frame, as well. in your case, the flange only has to be trimmed, and not completely removed, to overlap the 1x.

instead of a 1x, you could just use a shim of whatever depth necessary to make the gyp flush with the outside of the window frame.

maybe just enough shim to have an 1/8" overlap between the gyp. bd. and the window frame.

or fur that whole wall out, but you might not be willing to add the extra expense of adding an extra layer of 1/4" drywall over the 5/8 , especially because that wall is double height, right?

I vote for a sky hook! That way you can eliminate all the fussing with glu-lams, flitch plates, an other assorted structuarl considerations. The sky hook works every time!

mleitner, don't know if you got what you wanted yet, i got caught up in office holiday party bs on friday.

i & others in the office here have done this detail in two conditions, in stud frame & cmu. the pic above shows the jamb on cmu, i couldn't find one with all stud frame but i can explain it.

The windows in the picture shows bronze anodized aluminum widows & unlike what evilplatypus said there is no additional jamb framing. you're just seeing the actual window frame.

With standard type widows in these conditions we'll order the windows them specifying which fin to remove & then attach through the frame, if the window is operable it's easy & clean to do. a fixed frame may be difficult depending on the thickness of the window frame and the size of the drill the framers are using.

This is similar to the way dammson has shown but unlike his sketch the both the jack & king studs are in the wall.

your gyp bd will butt into the frame and the clauk covers your minuscule gap. The same with the exterior finish material which usually have a trim piece be it either in stucco on whatever siding you have (please don;t say 'EIFS').

Now, the fact that Vinyl windows are in play worries me, do you have control over that? there are inexpensive aluminum windows available... just a thought 'cause they have caused problems so many problems in the past that we won't even touch 'em... too much flex in the frames.

tsquared,

That photo shows your office's work? very nice.

We have no leeway on the choice of windows - they have to be the vinyl. The main concern on this project is affordability and we are doing what we can to produce some architecture in the process.

I think we will stay with the standard detail since it will produce the cleanest result, given the conditions we have. But I will definitely save your detail for future reference.

Milgard does have a nice, cheap, and thin profile alum window (w/thermal break and a U-value of .33 for a fixed window). However, count on 10% of them to leak at some point and at least 20% of them to arrive on the jobsite in the wrong sizes (even with shop drawing review).

They do have a lifetime warranty, which is nice but it generally involves a band aid with a caulking gun and not replacement.

totally understand,about the dollar signs, i get harped at about it all the time since we also build the projects.

dammson, i can't really say about the initial cost but if its a just a couple dollars difference aluminum is worth it in the long run, you won't be replacing them in a year (okay prolly an exageration but i know our company has had to replace every vinyl window and that costs doubl sice you have to rip out & redo the finishes)

We use Alenco on our low budget and spec homes/townhomes. a basic single hung 3050 w/ low-e costs us 82.19. since mleitner's window is in a stair the tempering would cost almost double.

We are planning under "Green Communities" guidelines and need to comply with Title 24. For one of those we need to spec "Energy Star" rated windows. Vinyl windows have that rating - aluminum don't.

Wood Framing Detail

I am looking for a wood framing detail in which a window sits right in the corner of two walls.

Does anyone have one on hand?

need more info... can you find a picture on the internets of something similar?

Imagine this situation with only one window.

On the interior, the window frame would start right in the 90º corner of the two connecting walls.

your'e looking for a cantilever detail, basically. that's not going to be a standard framing condition. will take some engineering thinking beyond normal framing rules. you don't have an engineer?

just make one up.

i'd probably use a post (or triple stud) on either side of the window and cantilever the header.

the header(s) might have to be pretty hefty, though, depending how much wall/ceiling/roof above it you're supporting. you don't want the corner to sag. and the ends of the headers over each 1/2 of the window will have to be tied together in a rigid way.

do you still want a support column in the corner or two structural beam headers canted and the windows are a storefront system or a special field mull?

the column in the corner is typical for standard windows with a nail fin & the column can be either wood or steel...

pretty much what jafid mentioned

i think he wants no column.

you can always fabricate a metal break around the column and make the units look like one windowor trim it in the same mat'l

are you trying to get to this...

...but in wood framing?

did you take into account how ugly thats gonna look?

with stick construction, it's really not a good place for a window because all of the weight from above the corner will have to be absorbed by the header and transfered to the support on either side of the window. that could be a substantial amount of weight. you'd have to design the header almost like a beam. corner windows (unless very small) are more suitable for frame construction.

thank you mr. know it all.

vado, i deserved that.

Steven, no window around the corner and no FLW either.

I have a 36" staircase with an exterior wall on the one and an interior wall on the other side. To get in some light (and make my facade work) I wanted to make the window as wide as possible. I was hoping there was a simple way of spanning the window across the full 36".

This is affordable housing, so it would have to be a simple solution. (Third and top floor.)

oh. yeah, just typical header framing in't?

this is how mdler rolls...

http://farm3.static.flickr.com/2120/2110606675_0591562190.jpg?v=0

can you draw us how you want it to look in plan? i still dont follow

Do you want the frame recessed so that the glass is the full 36" width or can you just install the window frame between the 2 walls?

Both can be done but the 2nd option is easy/standard stuff.

whats your occupancy is that a single family?

I dare not say what window...

it's Milgard, white vinyl.

Typically I have been staying about 3" clear of corners with all windows and doors to accommodate for double studs. I was hoping you could push these into the corners so that the window (incl. frame) is 36" wide.

metamechanic - is your CAPS still on from noting plans?

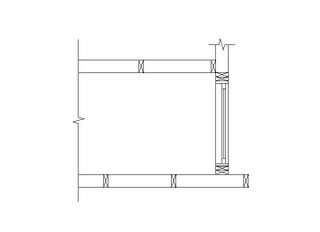

You mean like these? This is a very risky detail and not suitable for wet climates. Really, it's not that hard, but an engineer will have to size not only the cantilevering headers (allow 2/3 backspan), but also the hanger/Simpson tie where they meet at the corner depending on the size of the opening:

You may be able to get away with (2) 2x8s for the header (small corner window) but might have to have a PSL, LSL, or even a glulam for larger cantilevered openings.

Another thing to be careful of is the window - most manufacturers won't make this window or will make it but won't warranty it. You & your client have to measure the risk and put some faith in the glazer, window installer/manuf. and the sealant at the glass on glass corner. Good luck.

nice detail, dml.

It's just plain vinyl windows. No siding.

Just for my understanding: how would you place the studs at the T-intersection of the two walls? In our standard detail the stud prevents you from placing the window right into the corner.

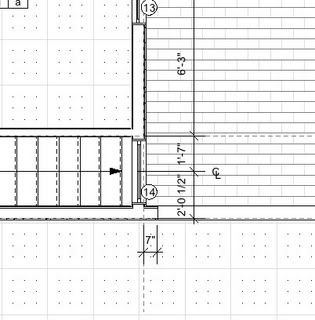

Hadn't realized we didn't have a plan detail.

Here is a quick sketch of how we would typically do it:

PLAN VIEW

to span the 36" you dont need a jamb stud, you already have a meaty corner post assembly. your sill will butt into that and you'll jack stud to the plate. Just shim tight. Im still confused about the corner - you want the glass to for a right angle or (2) window units to form a right angle? Does milgard even make a corner window?

As for the header - it depends a lot on the roof but really a plywood sheathed diaphram whith tension straps or if it goes to clg hgt just canteliever some joist out and be done.

are you trying to do something like this detail? where the patio door is? like you're trying to make an 'invisible jamb'?

it seems like this may not be the best solution for an affordable project especially with vinyl windows. you are still going have to trim the vertical out, and will not have any control about how each window is placed in the field. it's gonna be tough to get any kind of clean interior finish to look seamless, and the exterior resolution of how the siding and/or trim will be awkard at best.

The question is: where does the nail-fin of the window assembly attach to. How about the window flashing? You got an inside corner there.

I understand your pain; this condition is no big deal in masonry type construction but in wood frame construction? To come up with a detail that does not leave some 2" wide stucco or drywall on the side of the window is a real challenge. What dml is showing is very nice but custom and when you look at the left side of the window, 1st photo, you will notice that left-over strip of drywall that spoils the fun. I bet you in plan this glass was going right against the wall.

tsquared vixen

Can you share the detail of that vertical window over the patio door? Wood frame construction? How did you flash that window frame? You got all the conditions mleitner is looking for right there.

Pluk, emaze, yes! That's my problem.

I noticed that about dml's image too. The two glass panes meeting distract from it a bit. I guess posting the window corner showing two windows was misleading. It is just one window in my situation.

The horizontal window in tsquared's photo seems to be exactly the condition I am trying to achieve - just using vinyl windows in wood framing. As emaze said, the tolerances will probably ruin the look.

Thanks for the input though - I will definitely save this thread for future reference.

It appaers in tsq pic theres still a 3/4 jamb - painted black it looks flatter

It really isn't that complicated. It needs two cantelievering headers meeting at the corner. It can be doe in wood but probably easier to done in steel

could you frame the jack stud to support the header within the bottom plate of the exterior wall?

meta, thanks for your help.

i've never done it so i'm just throwing ideas around. can you use a vinyl retrofit window that are finless and can be screwed through the frame and into the jamb, sill, and head?

in the wall that extends past the window, i'll call it wall A, the one at the bottom in your drawing, can you:

-nail a 1x on 2-2x4 blocking/jamb. (the 1x becomes a spacer so that the 7/8" plaster ends and overlaps the window frame by about 1/8")

i'm also assuming that the exterior is plaster

-wrap flashing over the 1x and out, covering the 1x and portion of wall A. flash the head, sill and the other jamb per standard practice.

-install the window by nailing through the frame. the window installer should know where to put all neccessary sealants.

-install lath and plaster ground against the window frame. the plaster ground will be the barrier between the plaster and the window frame. you will have to add a nailer in Wall A for the plaster ground to nail onto.

inside, i'm assuming it will be 5/8" drywall, the drywall will end at the 1x. and since the 1x is thicker than the drywall, there will be a reveal. i don't know the best solution. i just wanted to point out the difference in dimensions and the 1x will be exposed inside, unlike the overlap that is happening with the plaster and the frame.

?

again, i'm just tossing ideas around.

using finless retrofit windows

i like that. it wouldn't necessarily have to be plaster on the exterior. it could be siding. instead of a 1x, you could just use a shim of whatever depth necessary to make the gyp flush with the outside of the window frame.

also, you might be able to use a window with the fins if you think the 1x is wide enough as a mounting surface for the fin and that the 1x will not split after you drive a screw in. might have to drive the screw angled towards the 2X. milgard's installation instructions for their flanged windows says that if necessary, the fins may be cut off, which makes me wonder whether those flanged windows can be mounted with screws through the frame, as well. in your case, the flange only has to be trimmed, and not completely removed, to overlap the 1x.

maybe just enough shim to have an 1/8" overlap between the gyp. bd. and the window frame.

or fur that whole wall out, but you might not be willing to add the extra expense of adding an extra layer of 1/4" drywall over the 5/8 , especially because that wall is double height, right?

or 1/4 inch furring strips over the studs, instead of drywall.

a lot of work to hide a gap...

I vote for a sky hook! That way you can eliminate all the fussing with glu-lams, flitch plates, an other assorted structuarl considerations. The sky hook works every time!

this guy had a hell of a sky hook.

mleitner, don't know if you got what you wanted yet, i got caught up in office holiday party bs on friday.

i & others in the office here have done this detail in two conditions, in stud frame & cmu. the pic above shows the jamb on cmu, i couldn't find one with all stud frame but i can explain it.

The windows in the picture shows bronze anodized aluminum widows & unlike what evilplatypus said there is no additional jamb framing. you're just seeing the actual window frame.

With standard type widows in these conditions we'll order the windows them specifying which fin to remove & then attach through the frame, if the window is operable it's easy & clean to do. a fixed frame may be difficult depending on the thickness of the window frame and the size of the drill the framers are using.

This is similar to the way dammson has shown but unlike his sketch the both the jack & king studs are in the wall.

your gyp bd will butt into the frame and the clauk covers your minuscule gap. The same with the exterior finish material which usually have a trim piece be it either in stucco on whatever siding you have (please don;t say 'EIFS').

Now, the fact that Vinyl windows are in play worries me, do you have control over that? there are inexpensive aluminum windows available... just a thought 'cause they have caused problems so many problems in the past that we won't even touch 'em... too much flex in the frames.

tsquared,

That photo shows your office's work? very nice.

We have no leeway on the choice of windows - they have to be the vinyl. The main concern on this project is affordability and we are doing what we can to produce some architecture in the process.

I think we will stay with the standard detail since it will produce the cleanest result, given the conditions we have. But I will definitely save your detail for future reference.

i think milgard aluminum are cheaper than their vinyl...are standard aluminum windows generally cheaper than vinyl windows?

Milgard does have a nice, cheap, and thin profile alum window (w/thermal break and a U-value of .33 for a fixed window). However, count on 10% of them to leak at some point and at least 20% of them to arrive on the jobsite in the wrong sizes (even with shop drawing review).

They do have a lifetime warranty, which is nice but it generally involves a band aid with a caulking gun and not replacement.

ml,

totally understand,about the dollar signs, i get harped at about it all the time since we also build the projects.

dammson, i can't really say about the initial cost but if its a just a couple dollars difference aluminum is worth it in the long run, you won't be replacing them in a year (okay prolly an exageration but i know our company has had to replace every vinyl window and that costs doubl sice you have to rip out & redo the finishes)

We use Alenco on our low budget and spec homes/townhomes. a basic single hung 3050 w/ low-e costs us 82.19. since mleitner's window is in a stair the tempering would cost almost double.

We are planning under "Green Communities" guidelines and need to comply with Title 24. For one of those we need to spec "Energy Star" rated windows. Vinyl windows have that rating - aluminum don't.

Block this user

Are you sure you want to block this user and hide all related comments throughout the site?

Archinect

This is your first comment on Archinect. Your comment will be visible once approved.